Best practices of technology support

Basic materials

- Support provided by

- Korea Institute of Science and Technology

- Beneficiary company

- Company A

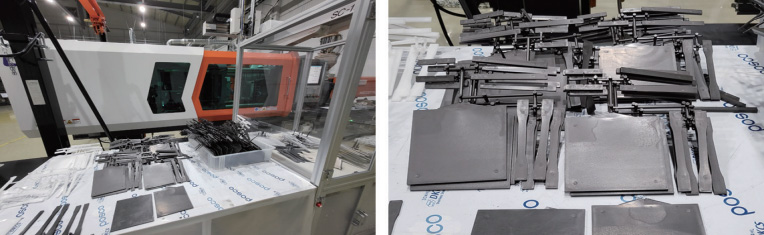

Carbon-polymer composite materials / Heating panels and mass-produced products

-

Technology issuesThe company requested technology support to develop the optimal composite materials to improve flame retardancy and manufacture high-performing and price-competitive heating panels.

-

Technology supportSupport for developing the optimal recipe of carbon-polymer composite materials of high thermal conductivity and flame-retardancy

Technology support for developing heating panels of carbon-polymer composite materials

Technology support for injection molding process of composite materials using equipment of the public institute

-

Outcomes of technology supportExcellent thermal conductivity and flame retardancy of composite materials in horizontal/vertical directions

Established the mass production system of carbon-polymer composite materials and heating panels for commercialization- - 2 units of extruders for mass producing carbon-polymer composite materials: Capa. 13,300 tons/year

- - 8 units of injection molding machines for mass producing heating panels: Capa. 10,400 tons/year

Sales (Oct. 2021 – Feb. 2022): 400 million KRW, Employment creation: 15 employees

Advanced materials

- Support provided by

- Korea Institute of Materials Science

- Beneficiary company

- Company B

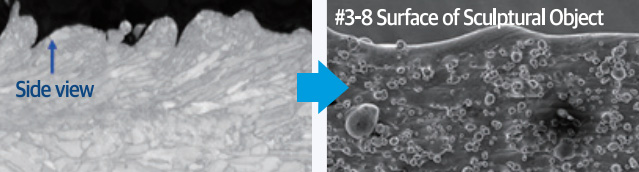

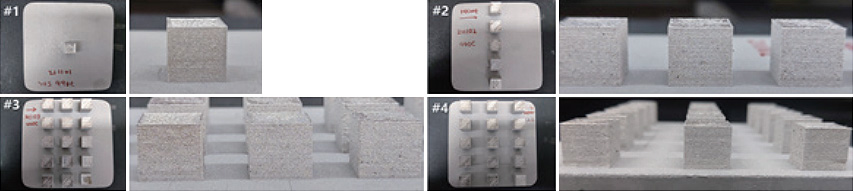

Improved surface quality by controlling 3D printing process conditions

-

Technology issuesThe company requested technology support and advice to address issues of quality deterioration of the products and increase in the cost of prototype development due to rough surface and defects on the surface of the 3D-printed objects.

-

Technology support The causes of defects on the surface of the objects are identified. The surface quality of 3D-printed objects is improved by controlling process conditions including the arrangement of objects, powder filling rate, and gas flow rate.

Surface of objects according to process conditions of 3D printing

-

Outcomes of technology supportReduced cost and defect rate thanks to improved surface quality of the objects

- - Saved 24 million won as prototype development took 6 months less

- - Defect rate of the object manufacturing is decreased by about 30%.

Electronic components

- Support provided by

- Korea Electronics Technology Institute

- Beneficiary company

- Company C

VCSEL chips and modules

-

Technology issuesSince there are no clear reliability evaluation methods of VCSEL, the company requested technology advice for VCSEL lifetime evaluation and warranty life calculation to ensure the reliability of their products.

-

Technology supportThe causes of errors in the company’s reliability evaluation are analyzed. Arrhenius model is applied to a new formula for accurate lifetime prediction. Analysis of VCSEL reliability database found that the failures of VCSEL have to do with degradation. Data analysis methods using B10, B50 reliability levels and Weibull distribution that are suitable for degradation are proposed.

-

Outcomes of technology supportEstablished reliability evaluation and data analysis methods can provide accurate reliability data to companies. High reliability can lead to new export trade partners.

- - Sales of 6.7 billion KRW in 2020. Sales of 9.1 billion KRW in 2021. Forecast of 12 billion KRW in 2022.

- - Addressed issues in commercialization process by providing objective reliability data demanded by the companies

Modules and components

- Support provided by

- Korea Automotive Technology Institute

- Beneficiary company

- Company D

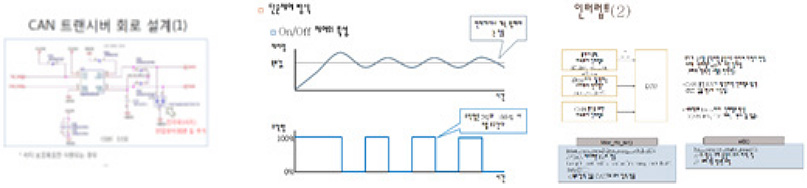

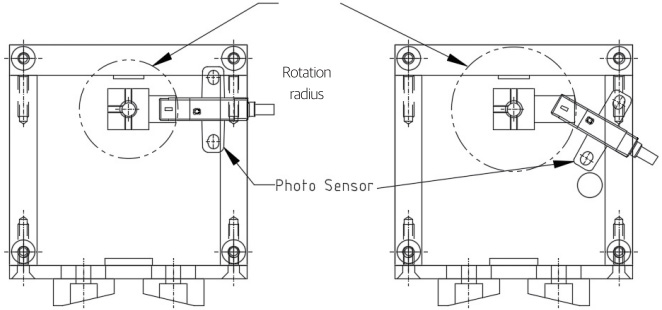

Advice on new technologies

-

Technology issuesThis muffler company has worked on expanding its business based on electric and electronic control. However, there is a lack of technology expertise and experts in control board design and software logic implementation as well as insufficient equipment for performance evaluation of working samples and prototypes.

-

Technology supportSupport for PID technique-based software for motor control and practical technology implementation methods

Technology advice on motor control theory and design circuit

-

Outcomes of technology supportPioneered new industries and businesses to generate profits and enhance the value of the company

- - Acquired practical design skills for new technologies

- - Provided guidance for component development design

System and equipment

- Support provided by

- Korea Electrotechnology Research Institute

- Beneficiary company

- Company E

Numerical analysis and design of electric fields/ Analysis and design of magnetic devices

-

Technology issuesIntegrated magnetic grippers and sensors lack advice and verification by professional institutes to ensure reliability. The company requested technology advice for comprehensive evaluation of their products.

-

Technology supportAnalyzed magnetic devices and results of experiments on magnetic devices and supported the design to present the major direction for technology development

Technology advice on product improvement plans based on experimental data

-

Outcomes of technology supportEstablished technology advancement method based on experiences of technology development

- - Product development period is shortened by 3 months and labor cost for technology development is saved by 100 million won.

- - Technology transfer agreement is made through technology development.